These are exciting times in automobile logistics. E-mobility is competing with the internal combustion engine, standards of climate and resource protection are rising and the digital transformation is creating new business fields. In 2020, the Regional Comprehensive Economic Partnership (RCEP) in the Asia-Pacific region created the world’s largest free-trade zone, with currently 2.2 billion people. And then a global pandemic arrived on top of these fundamental transformations – triggering volatile reactions on the markets.

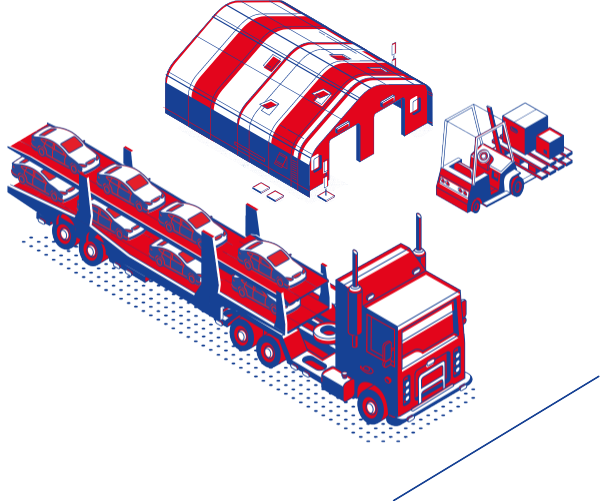

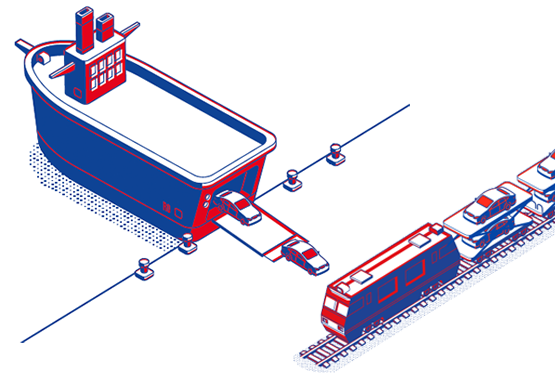

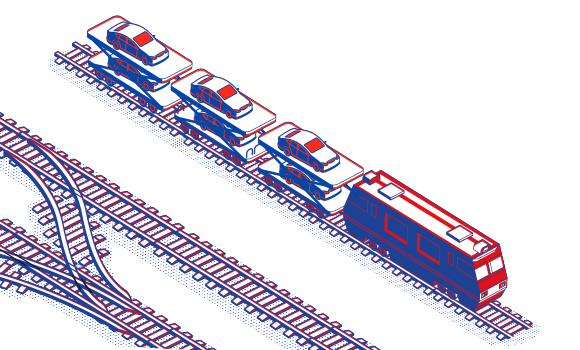

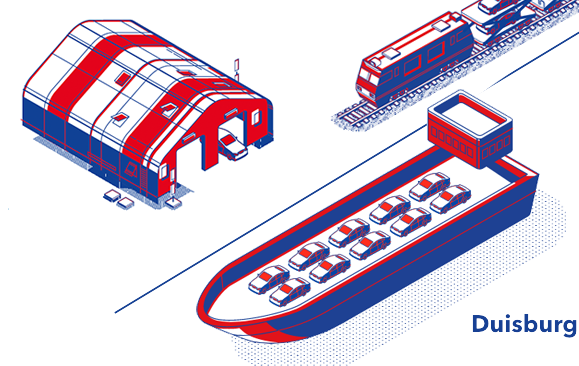

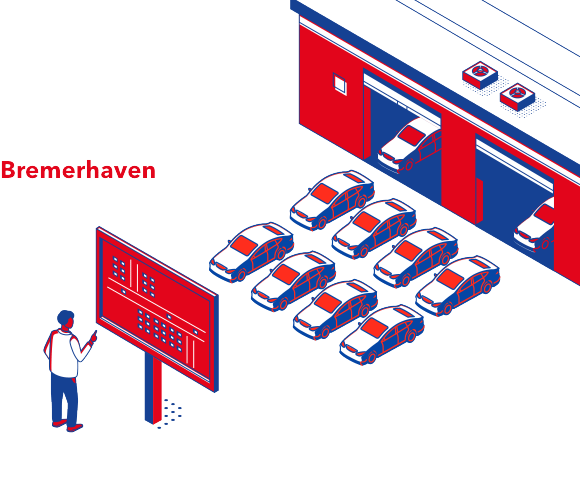

As a global logistics service provider, BLG is in the business of negotiating these opportunities and risks. The company loads and unloads more than 1,400 car carriers and operates 1,500 of its own AutoRail wagons, 560 trucks and seven barges on the Rhine and Danube per year. At BLG, the wheels never stop turning. Not least because we don’t just react to change, we proactively shape the future ourselves. With smart digital solutions and sustainable concepts for climate-friendly transport. The company consistently develops and expands its logistics network so that it can offer services on all forms of transport from one source.

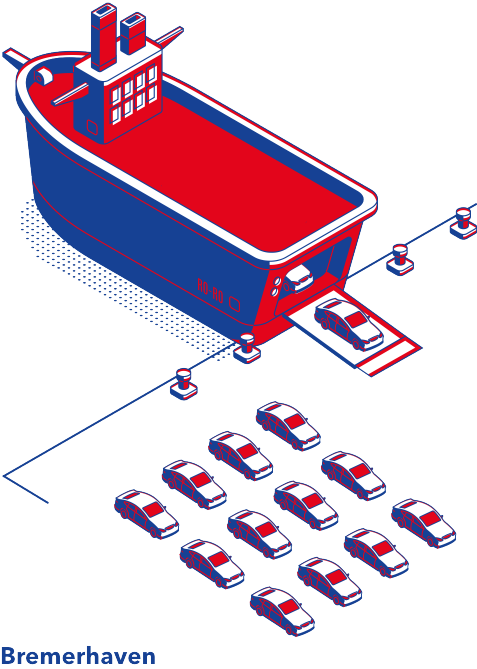

Transports go through a large number of national and international BLG locations. Here, we take a closer look at four examples: The first is Bremerhaven. It’s the largest hub and a base for international departures and arrivals. St. Petersburg, the gateway to Russia, the Caucasus and other CIS states. This is a market BLG penetrated even further in 2020. Falkenberg is the heart of our rail-bound logistics, an area which is becoming increasingly important for our customers’ climate goals. The inland port of Duisburg is a modern turnstile for vehicles from the factories of various car manufacturers in the Czech Republic and Slovakia – and the German terminus of the New Silk Road.